There are economic and environmental benefits of drying biosolids, sludge, and subproducts. In municipal and industrial facilities, the K-S/UPE Paddle Dryer is reducing the cost of disposal and conversion of waste into marketable subproducts. The K-S/UPE paddle dryer provides a reliable and efficient method for drying filter cakes and centrifuge concentrates. As remediation, it is used to remove hazardous volatile organics.

– Reduced weight

– Reduced volume

– Reduced landfill fees

– Removal of hazardous volatile organic compounds

– Production of Class A biosolids of exceptional quality (EPA recognized as PFRP)

– Conversion to beneficial products

– Waste recovery

– Production of an autogenous material

– Generation of alternative fuel sources

The chemical, petrochemical, pharmaceutical, food, metallurgical, mineral processing, pulp and paper industries, as well as municipalities, are using the K-S/UPE Paddle Dryer to dry:

- Biosolids fibers and fillers

- Food Waste Oily Waste

- Hydroxides Metal Oxides

- Dredging and Soil Process Residues

A successful workfield depends on the integration of the process units with the properly selected ancillary equipment and the correct design of the facilities. Reliability, ease of operation, rugged construction, performance, and superior customer service are hallmarks of a K-S/UPE facility.

– K-S/UPE can provide a complete sludge processing workingfield, including equipment for pumping, thickening, dewatering, drying and gas processing.

– Almost 30 years of successful experience in sludge drying in numerous facilities around the world.

– Weight reduction of 83% is achieved during drying from 15% dry solids to 90% dry solids.

It has an impact on cost-effectiveness and it’s environmentally friendly, ensuring:

- High thermal efficiency

- Minimum gas outlet volume

- Low gas temperature

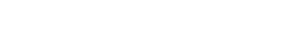

Indirect dryers have a metal wall that separates the process mass from the heat source (steam, water or oil). High thermal efficiency is obtained because the heat from the thermal part goes directly into the process mass. As the material comes into contact with the heated trough and agitators, the process mass is heated by conduction; with an isolated dryer, few heat is lost. Exhaust gas is minimal at low temperature. Therefore, the volume of non-condensable gas from the dryer, which may require treatment, is minimal.

The K-S/UPE Paddle Dryer is an indirect heat transfer device that employs a lot of mechanical agitation to improve contact with the product being dried. Evaporation rates per m² of heat transfer surface are maximized through self-cleaning of the blades and the mixing effect.

The movement of process material between the inclined surfaces of the wedge-shaped rotating blades generates shear forces, which clean the blade surfaces and maximize conductivity. Counter-rotating shafts move material away from the walls, cleaning the walls via the tab on each paddle. This results in higher heat transfer rates than disc or single-shaft dryer designs.

The wedge-shaped blades and the interlocking of the two agitators create a localized mixing effect around the blade.

This allows more individual particles in the bed to be exposed directly to the heat transfer surface, thus increasing the heat transfer rate, allowing the use of smaller equipment.

Double counter

Rotary shafts with the interlocking of the wedge-shaped blades produce homogeneous mixing and optimize heat transfer.

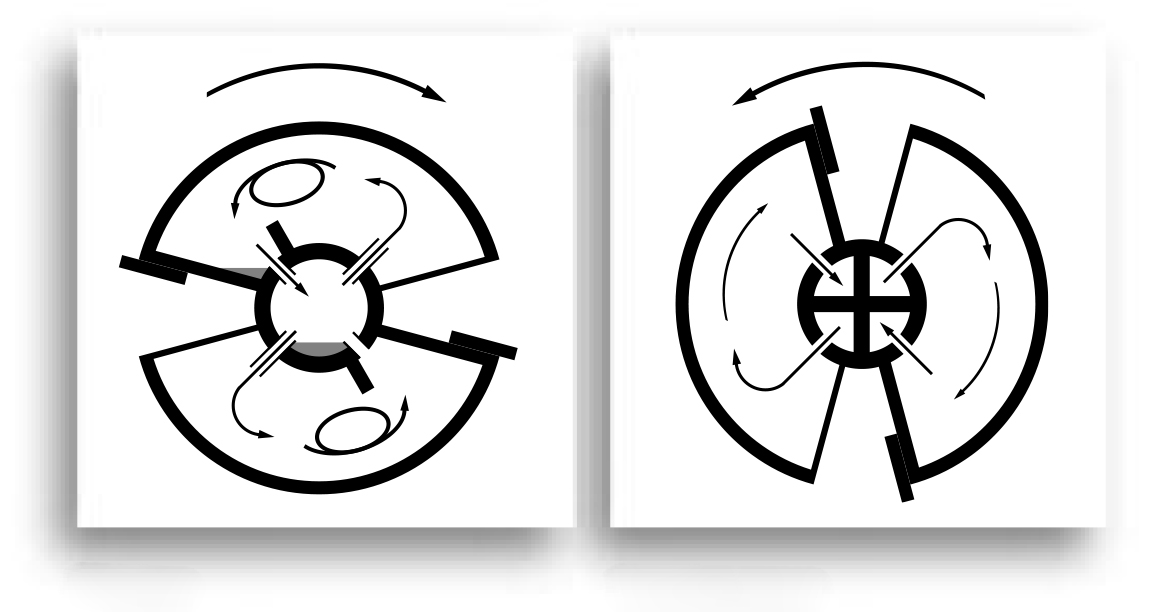

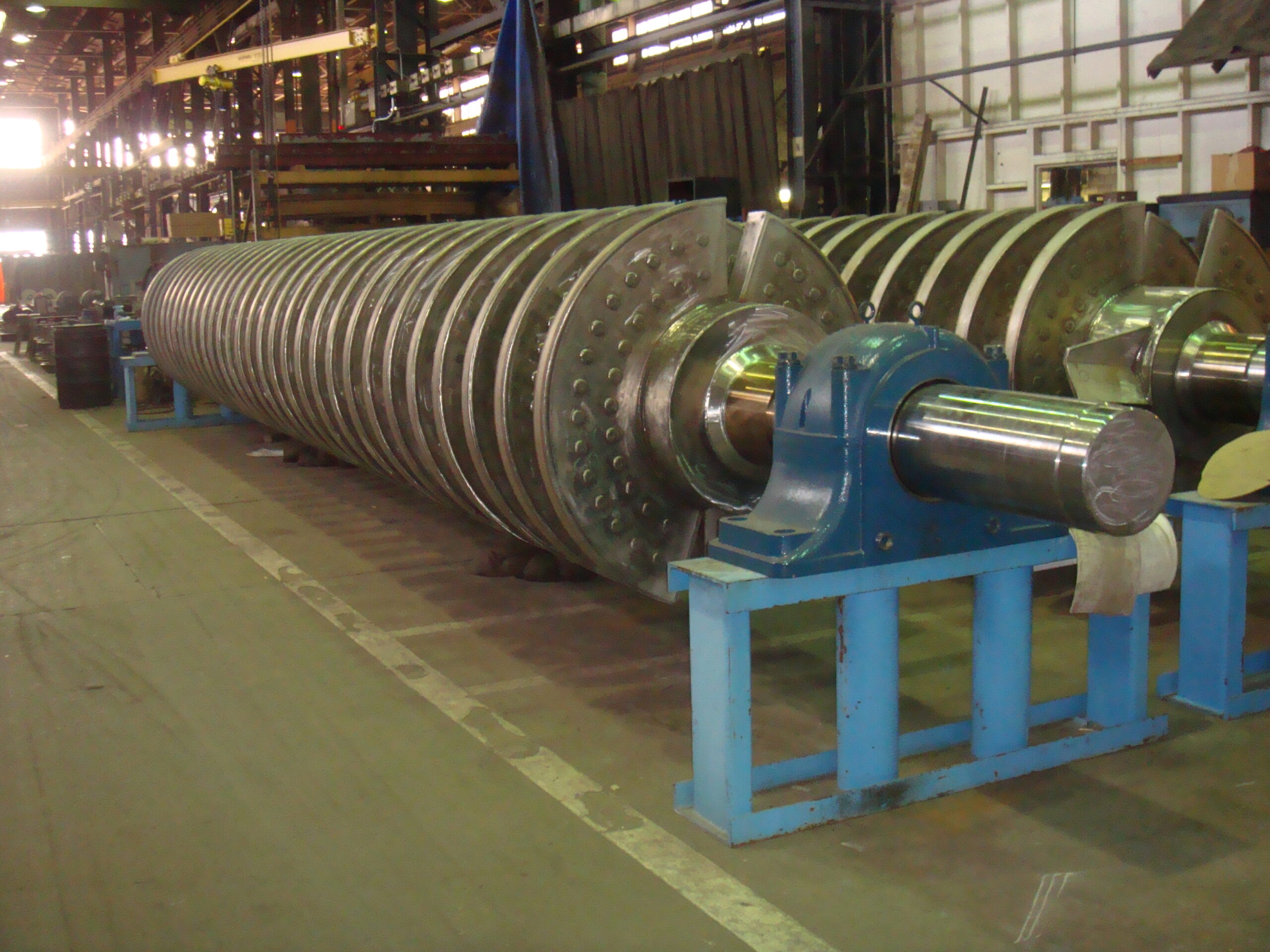

8W Model – 390 square feet of heat transfer area.

Dual shafts rotating in opposite directions with single hollow core interconnecting wedge-shaped blades produce homogeneous mixing, optimize heat transfer and provide an additional self-cleaning feature. A large heat transfer is achieved through the area/volume ratio by the use of hollow paddles and a jacketed container, from which the heating medium flows. The result is an efficient and compact machine with less space required and lower installation costs.

– Reduces particles

– Allows full use of the drying area

– Minimum volume of non-condensable gases

– No external sweeping gas

– Low temperature exhaust

– High torque

– Low speed

– Steam enters the hollow shaft through a rotating joint and is distributed evenly across all blades. Steam enters the blades regardless of their orientation and condensate is removed with each revolution/cycle

– Hot oil (thermal fluid) enters and leaves the hollow shaft through a rotating joint. Liquid supply pump pressure through the hollow blades, regardless of orientation.

– Steam

– Hot oil

K-S/UPE Process and Design Engineers provide assistance in all phases of the project. Depending on your specific requirements, K-S/UPE can supply a dryer or a complete drying system. K-S/UPE can provide pilot testing in our laboratory or at your factory.

– Steam from 30 to 200 psig (or higher)

– Hot oil up to 750° F

– Dry to 99+% dry solids

– Partially dried to achieve autogenous conditions

– Produce a product of any degree of intermediate drying

– The product may approach the temperature of the heating medium

– Continuous process on a one-time basis

– Sludge

– Folders

– Cakes

– Granules

– Posts

– No fugitive emissions

– Atmospheric, vacuum or pressure designs

– Systems purged with solvent recovery

The K-S/UPE Paddle Dryer transports materials with different handling characteristics, including sticky materials.

Preconditioning sticky materials by mixing with recycled dry product to make it transportable is not mandatory. This results in lower investment, lower operating costs and lower maintenance costs.

As sludges dry, they undergo a series of transitions in their handling characteristics. These changes are directly related to the solids content. For example: extremely wet sludge and extremely dry sludge require substantially lower torque than sludge in the plastic – or sticky – phase, which requires high torque. The K-S/UPE Paddle Dryer is designed with high torque feature to increase your process flexibility. Extra torque maintains safe operation even if adverse conditions present themselves.

The material is normally transported through the K-S/UPE dryer by displacement. As material is added to the dryer, it is settled into the bed by the mixing action of the agitators.

Pressure from the hydraulic head, combined with the action of the wedge-shaped blades, pushes material around and through the blades. Although there is a lot of agitation and some back mixing, the overall flow pattern can be described as a flow movement from the plug to the dryer outlet.

For fast-drying material, where very high volumes need to be conveyed, the paddles and dryers can be tilted to increase the conveying rate.

– Easy to operate

– Requires minimal supervision

– Simple instruments monitor the process

– High efficiency

– Low volume of effluent gas

– Designed for high torque and low operating speed

– Simple durable design for easy, low maintenance

– No internal parts to adjust or maintain

– No metal-to-metal contact

– Shafts, housing bearings and drive components are designed for long life under harsh conditions, ensuring long-term mechanical integrity

– Robust structure supports split bearings

– Stuffing boxes with grease purge. Alternative fence designs are used

– Compact

– Small gas outlet system

– Removing the vertical axis reduces civil construction

– Designed, built and stamped per ASME or PED Code

– Heat transfer areas from 3 to 300 square meters

– Carbon steel, stainless steel or alloy construction

– Abrasion resistant hard surface coatings are used